Silicon carbide crucibles and graphite crucibles are containers with good high-temperature resistance, which are usually more common in industrial metal smelting and casting. Compared with graphite crucibles, silicon carbide graphite crucibles are resistant to high temperatures and oxidation. Silicon carbide crucibles are larger than graphite crucibles and have a longer service life. Silicon carbide manufacturers produce silicon carbide, graphite crucibles, non-ferrous metal castings, and high-heat conduction crucibles. The size of the negative electrode material pre-carbonized crucible is 500*1200mm. Rongsheng manufacturers customize silicon carbide graphite crucibles.

Good Thermal Vibration, Corrosion Resistance, High-Temperature Resistance Silicon Carbide Crucible

Thermal conductivity: High thermal conductivity material is adopted, with dense structure, low apparent porosity, and fast thermal conductivity.

Long service life: Compared with ordinary clay graphite crucible, the service life of the same material can be increased by 2-5 times.

High Density: Using an advanced isostatic pressing molding process, the material is dense and uniform without defects.

High strength: material selection, high-pressure pressing, good high-temperature strength, scientific product shape, high pressure bearing capacity.

Corrosion resistance: Advanced material formula can effectively resist the physical and chemical effects of the melt.

Less sticky slag: There is less slag hanging on the inner wall, which greatly reduces the possibility of heat resistance and expansion of the crucible.

High-temperature resistance: the operating temperature is 400-1700°C.

Less pollution: The material design fully considers the relationship and process characteristics of the smelted metal, and contains almost or no harmful impurities.

Metal saving: Because the material contains special elements, it can effectively inhibit the oxidation of metals.

Energy saving and environmental protection: fast heat conduction can save a lot of fuel, reduce waste pollution, proper resistivity, and induction heating can significantly reduce reactive power loss.

High oxidation resistance: the advanced anti-oxidation mechanism makes the graphite in the crucible well protected.

How to Use the Silicon Carbide Crucible Correctly?

Many people do not preheat the new silicon carbide crucible when using it, which can easily cause the crucible to crack. So we must preheat the crucible before using it. So, how to preheat the crucible?

Preheating is to dehumidify the crucible. The new silicon carbide crucible can be placed next to the oil furnace for preheating 4-5 hours before use. Charcoal can also be burned in the crucible for about 4 hours before using a new silicon carbide crucible, which also dehumidifies the Lake Tana precious crucible. The temperature changes during the heating and preheating time of the new crucible furnace, and the temperature is slowly heated at 0°C-200°C for 4h. Heat slowly at 0°C-300°C for 1h. Heat slowly at 200°C-300°C for 4h. Heat slowly at 300°C-800°C for 4h. Heat slowly at 300°C-400°C for 4h. Rapid heating at 400°C-600°C for 24h. After the furnace is shut down, the preheating time of the furnace is as follows. Oil furnace and electric furnace: 0°C-300°C slow heating for 1 hour, 300°C-600°C slow heating for 4 hours, and when the temperature is above 600°C, it can be heated quickly to a certain degree.

When using a silicon carbide crucible, it must be operated in accordance with the operating procedures in order to better create more value for the silicon carbide crucible and bring more economic benefits.

650KG Silicon Carbide Graphite Crucible Manufacturer

The main products of 650KG silicon carbide graphite crucible manufacturers include graphite crucibles, graphite block rods, graphite molds, graphite rotors, and other processed parts. There are more than 200 varieties of non-standard graphite customized parts, silicon carbide products, special impregnated graphite products, vacuum furnace body parts, etc. These products are widely used in the non-ferrous metal smelting industry, experimental instrument industry, jewelry industry, and high-temperature industrial furnace industry. Machinery industry, glass machinery industry, new materials and new energy industries such as electronic semiconductors, special ceramics industry, diamond tool industry, aviation industry, etc.

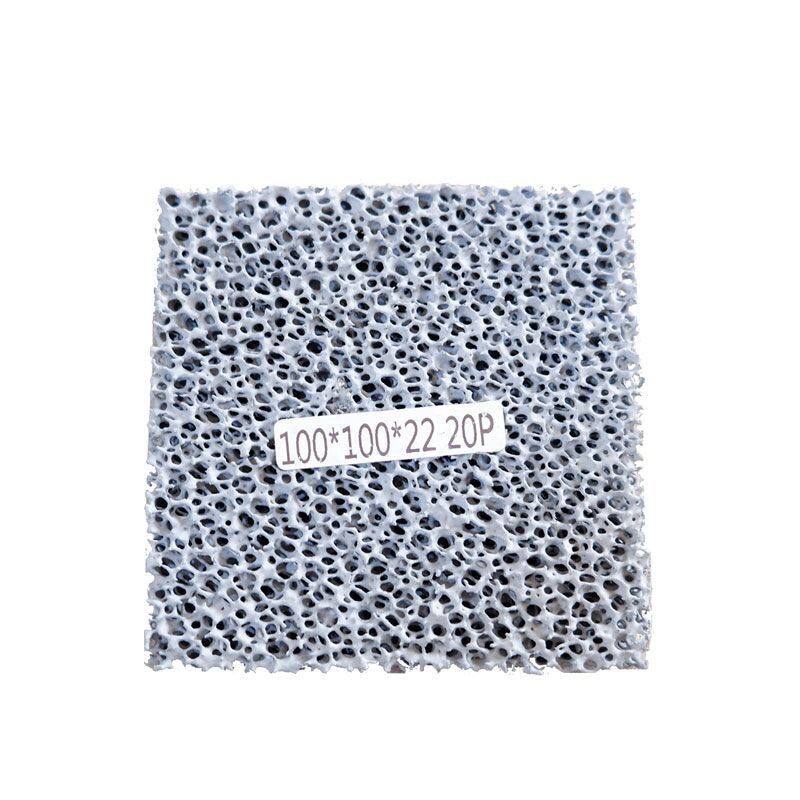

New isostatic silicon carbide graphite crucibles, standard sizes. High-temperature resistance, wear resistance, thermal shock stability, and high flexural strength. It can be used in electric power, slag flushing trenches in steel mills, the coal chemical industry, and mines.

Silicon carbide products have strong stability. Silicon carbide graphite crucible, made of high-strength silicon carbide, has good load-bearing capacity. It has a higher charge softening temperature and a smaller re-burning rate of change.

Silicon carbide products have a long service life. Silicon carbide graphite crucible has the characteristics of a high load softening point, fast heat conduction, anti-oxidation, not easy to shrink and deform at high temperatures, and long service life.

Silicon carbide products, are not easy to scale and are more durable. The silicon carbide graphite crucible material produced by Rongsheng has a smooth surface and no pores, and the internal flow channel is smoother, less prone to fouling, and the atomization is more uniform.

Isostatic pressing of special crucible for electric furnace

Rongsheng Manufacturer is a professional crucible manufacturer. By introducing advanced production technology, using high-quality raw materials, and applying isostatic pressing technology to produce various types of crucible products. The main products include silicon carbide graphite crucibles, clay graphite crucibles, high-purity graphite crucibles, etc. The products are widely used in the smelting of pure aluminum, aluminum alloy, copper, lead, zinc, gold, silver, and other non-ferrous metals. The silicon carbide graphite crucible produced by Rongsheng has good thermal conductivity, long service life, and significant energy saving, which greatly saves the production cost of the enterprise.

Rongsheng Manufacturer Customized Silicon Carbide Graphite Crucible

If you need to customize a silicon carbide graphite crucible with special size or shape, please provide a description of the use conditions, size, quantity, thickness, and other information of the silicon carbide crucible product in advance. We can process and customize according to the drawings, manuscripts, and CAD/PDF drawings you provide. Since we need to grind and cut in the process at home, the process will cause certain tolerances, which are generally small. If you choose the exact size, please also inform us in advance.

Silicon Carbide Crucible for Non-Ferrous Smelting and Powder Metallurgy

Silicon carbide crucible adopts international advanced isostatic pressure crucible molding equipment and technology, high-quality refractory raw materials are selected, and high-tech formula is used. Silicon carbide crucible has the characteristics of high volume density, high-temperature resistance, fast heat transfer, acid and alkali corrosion resistance, high-temperature strength, high oxidation resistance, and stable quality. The service life is 3-5 times that of a clay graphite crucible. It greatly reduces fuel consumption, reduces labor intensity, improves work efficiency, and creates better economic benefits.

Silicon carbide crucible supporting furnace type. It can be used in gas furnaces, gas furnaces, coke furnaces, oil furnaces, resistance furnaces, induction furnaces, oil furnaces, biological pellet furnaces, etc.

Silicon carbide crucible range of use. Melting all kinds of gold, silver, copper, aluminum, lead, zinc, and other non-ferrous metals, as well as medium carbon steel and various rare metal alloys. Silicon carbide crucibles are suitable for different processes in the non-ferrous metal industry. Therefore, silicon carbide crucibles are divided into professional copper-melting silicon carbide crucibles, professional aluminum-melting silicon carbide crucibles, professional zinc oxide silicon carbide crucibles, professional zinc-melting silicon carbide crucibles, professional tin-melting silicon carbide crucibles, and so on.