Fused zirconia corundum brick is a high-quality, high-temperature performance refractory material, mainly made of zirconia and alumina through arc melting. The adobe has the characteristics of high density, high hardness, high heat resistance, corrosion resistance, etc., and has good use effects in high temperature and chemical erosion environments. Zirconia corundum bricks are refractory bricks made of industrial alumina and zircon sand. According to the manufacturing process, zirconium corundum bricks can be divided into two types: fused zirconium corundum bricks and fired zirconium corundum bricks.

Properties and Characteristics of Zirconium Corundum Bricks

Fused zirconia corundum bricks are commonly known as white iron bricks, also known as corundum-deleyite bricks. The main chemical composition is Al2O3 50% to 70%, ZrO2 20% to 40%, and the rest is SiO2. The main mineral composition is baddeleyite (ZrO2), corundum (α-Al2O3) and glass phase. Baddeleyite crystallizes to form the backbone of the brick body, ZrO2 has a high melting point (2715°C), has good chemical stability, and has strong corrosion resistance to acidic and alkaline media, especially glass liquid.

physical properties

Fused zirconia corundum bricks have some excellent physical properties, which make them work well in high-temperature and chemically erosive environments. The following will introduce its main physical performance indicators:

density and hardness

The density of fused zirconia corundum bricks is generally between 35.6-4.2 g/cm3, which is a high-density material. At the same time, its hardness is very high, usually above 9.0 Mohs, which is three times that of steel. This means that it can also maintain good wear resistance under high temperatures and strong acid and alkali environments.

heat resistance

The heat resistance of fused zirconia corundum brick is also one of its main physical properties. The material can withstand very high temperatures, generally above 2200. This enables it to operate at high temperatures for a long time without deformation, cracking, etc.

Corrosion resistance

The corrosion resistance of fused zirconia corundum bricks is also excellent, mainly due to their good chemical stability and oxidation resistance. Fused zirconia corundum bricks have good corrosion resistance in corrosive environments such as acid and alkali, high temperature, and humidity, which makes them able to withstand more severe working conditions during production.

Preparation Process of Fused Zirconia Corundum Brick

The preparation process of fused zirconia corundum bricks is relatively complicated. It is necessary to select high-quality zirconia and alumina raw materials and mix them evenly. Next, the mixture is poured into an electric furnace for high-temperature electric fusion to form solid adobes. The electric melting furnace usually inserts two electrodes into the furnace body at the same time, generates high temperature through the electric arc in the furnace, heats the raw materials to a molten state, and forms a hard adobe after melting.

During the preparation process, special attention needs to be paid to controlling the conditions such as atmosphere and temperature in the furnace to maintain the uniformity of the melt and the stability of the chemical composition. In addition, the baking and processing of Adobe is also an important link affecting product quality, which is directly related to the physical performance parameters such as density and hardness of Adobe.

Application Field of Zirconium Corundum Brick

Fused zirconia corundum bricks are widely used in the industrial field, especially where high-quality, high-performance refractory materials are required in high-temperature and chemically aggressive environments. The following will introduce its application fields in detail from several aspects:

glass melting furnace

In glass melting furnaces, fused zirconia corundum bricks are usually used as important parts such as the upper pool wall, small furnace flat wall, small furnace stack, tongue wall, and parapet. This is because a glass melting furnace is a high-temperature, high alkalinity, highly corrosive environment that requires the use of high-quality refractory materials that can withstand long periods of operation. The fused zirconia corundum brick not only has excellent heat resistance and corrosion resistance but also can maintain good physical stability, ensuring the smooth progress of the glass production process.

Application of Fused Zirconia Corundum Brick in Glass Furnace

Fused zirconia corundum bricks are used in industrial furnaces such as glass-melting furnaces. The parts used in the glass melting furnace are the masonry of the upper pool wall, the small furnace flat wall, the small furnace stack, the tongue wall, and the parapet. The following problems should be paid attention to in the use of fused zirconia corundum bricks:

① Irregular changes in thermal expansion. The expansion curve of the fused zirconia corundum brick has an abnormal section near 1000°C. Its internal ZrO2 crystal undergoes reversible crystal transformation and has a large volume change. Therefore, bricks containing ZrO2 should not be used in places where the temperature often fluctuates sharply around 1000 °C. When baking the kiln, the temperature change should not be too large at 900-1150 °C. Generally, it cannot exceed 15°C/h, and a steady temperature rise is required. Some parts need to be protected from cold wind and need to be protected by other bricks to prevent bursting.

②Shrinkage cavity. During pouring molding, shrinkage cavities often appear at the gate, where the brick body has more pores and poor density. Therefore, when building the wall of the glass melting tank, the shrinkage cavity is all directed towards the inner direction of the kiln. If the sprue is facing outward, when the brick body is corroded to a very thin thickness, it will cause a glass liquid leakage accident. When used in the upper flame space of the pool kiln, the service life is very long, and the problem of glass liquid running out will not occur. Therefore, the spout is used outwards to prolong the service life.

③ eutectic. Fused zirconia corundum bricks are built in contact with clay bricks, and the eutectic phenomenon will occur at a high temperature of 1300 °C. Therefore, when choosing refractory materials, it should be avoided to contact the two refractory materials with serious eutectic phenomenon for masonry. If the silica brick is under the fused zirconia corundum brick, it is most susceptible to erosion by the fused zirconia corundum brick.

Sintered zirconium corundum bricks are also known as ceramic-bonded aluminum-silicon-zirconium bricks. Compared with fused zirconia corundum bricks, the chemical composition of sintered zirconia corundum bricks is similar. However, it has the advantages of no carbon, low content of glass phase, uniform structure, no shrinkage cavity, good thermal shock stability, and corrosion resistance.

Metallurgical equipment

Fused zirconia corundum bricks are also widely used in metallurgical equipment, especially in the iron and steel industry. For example, high-quality, high-performance refractory materials are required in equipment such as blast furnace interiors, converter interiors, heating furnaces, and dryers. Fused zirconia corundum bricks just meet this requirement.

aerospace equipment

Fused zirconia corundum bricks are also more and more widely used in aerospace equipment. For example, in high-temperature components such as engine nozzles and combustion chambers, high-quality ceramic materials are required to withstand high temperature, high pressure, and severe airflow erosion. The fused zirconia corundum brick has excellent heat resistance and corrosion resistance, making it one of the ideal materials for these components.

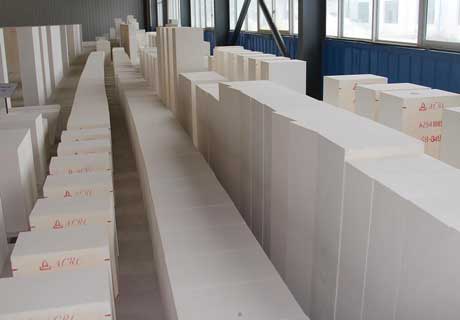

AZS Bricks Fused Zirconia Corundum Brick Fused Bricks

With the increasing demand for high-quality refractory materials, the market prospect of fused zirconia corundum bricks is also becoming brighter. Especially in the fields of glass, metallurgy, aerospace, and other fields, the application prospect is very bright. zirconium bricks series, Fused zirconia corundum brick is an excellent refractory material with high density, high hardness, high heat resistance, and corrosion resistance. It is widely used in industrial production. The preparation of fused zirconia corundum bricks requires fine control in multiple steps to ensure their excellent physical properties. Buy High-Quality AZS-Fused Zirconia Corundum Bricks Fused Bricks – Refractory Bricks for Glass Kiln, Contact us to Get a Free Quote.