Advantages of RP Graphite Electrodes For Sale in RS

1. Our product is made of high quality low ash materials, such as petroleum coke, needle coke and coal pitch.

2. From calcining, burdening, kneading, forming, baking to pressure impregnation, graphitization, we pay attention to every detail to make it boutique.

3. We know machining is very important, so we precision machined with professional CNC machining to make sure high quality.

4. Such of the products own characteristics with low resistivity, good electrical conductivity, low ash, compact structure, good antioxidation and high mechanical strength.

RP Graphite Electrode technical parameters

| Items |

Classification |

Unit |

Nominal Diameter (mm) |

| |

|

|

75-130 |

150-225 |

250-300 |

350-450 |

500-800 |

| Resistivity |

Electrode |

μΩm |

8.5 |

9 |

9 |

9 |

9 |

| |

Nipple |

|

8 |

8 |

8 |

8 |

8 |

| Bending Strength |

Electrode |

Mpa |

10 |

10 |

8 |

7 |

6.5 |

| |

Nipple |

|

15 |

15 |

15 |

15 |

15 |

| Young’s Modulus |

Electrode |

Gpa |

9.3 |

9.3 |

9.3 |

9.3 |

9.3 |

| |

Nipple |

|

14 |

14 |

14 |

14 |

14 |

| Bulk Density |

Electrode |

g/cm3 |

1.58 |

1.53 |

1.53 |

1.53 |

1.52 |

| |

Nipple |

|

1.7 |

1.7 |

1.7 |

1.7 |

1.7 |

| CTE (100℃-600℃) |

Electrode |

×10-6/℃ |

2.9 |

2.9 |

2.9 |

2.9 |

2.9 |

| |

Nipple |

|

2.7 |

2.7 |

2.8 |

2.8 |

2.8 |

| Ash Content |

|

% |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

Graphite Electrode RP Current Capacity

| Nominal diameter |

Permissible current power |

The current density (A / cm2) |

| Millimeter (mm) |

Inch (inch) |

| 300 |

12 |

10000-13000 |

17-24 |

| 350 |

14 |

13500-18000 |

17-24 |

| 400 |

16 |

18000-23500 |

16-24 |

| 450 |

18 |

22000-27000 |

16-24 |

| 500 |

20 |

25000-32000 |

15-24 |

| 600 |

24 |

30000-36000 |

14-24 |

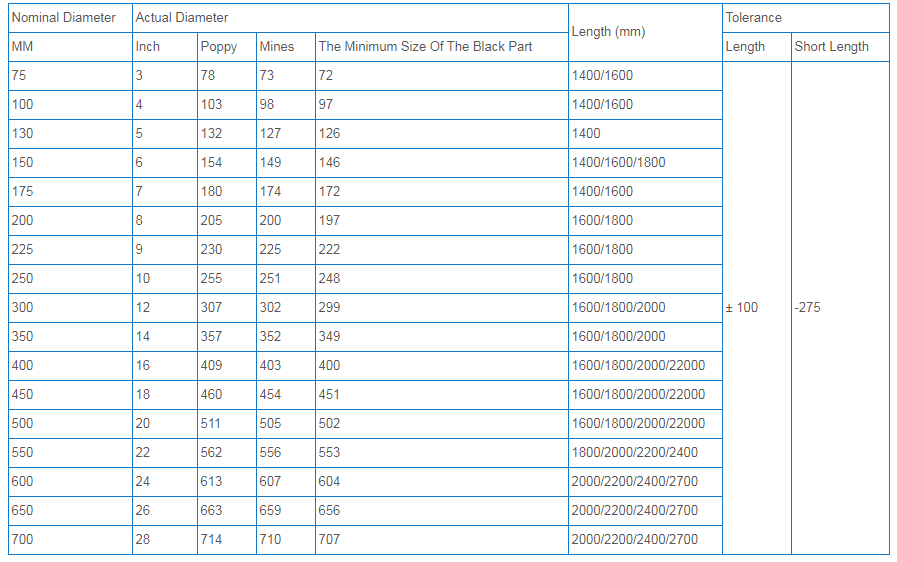

The Length & Diameter & Permissible Deviation of Graphite Electrode RP

| Diameter |

Length |

| Nominal diameter |

Actual diameter |

Nominal length |

tolerance |

| Millimeters (mm) |

Inch (inch) |

Max. (Max.) |

Min (min) |

mm |

Length |

the maximum |

|

| 300 |

12 |

307 |

302 |

1600 1800 |

± 100 |

-100 |

-275 |

| 350 |

14 |

357 |

352 |

| 400 |

16 |

409 |

403 |

| 450 |

18 |

460 |

454 |

| 500 |

20 |

511 |

505 |

1600/1800/2000/2200

1800/2000/2200

1800/2000/2200/2400

1800/2000/2200

1800/2000/2200 |

± 100 |

-100 |

|

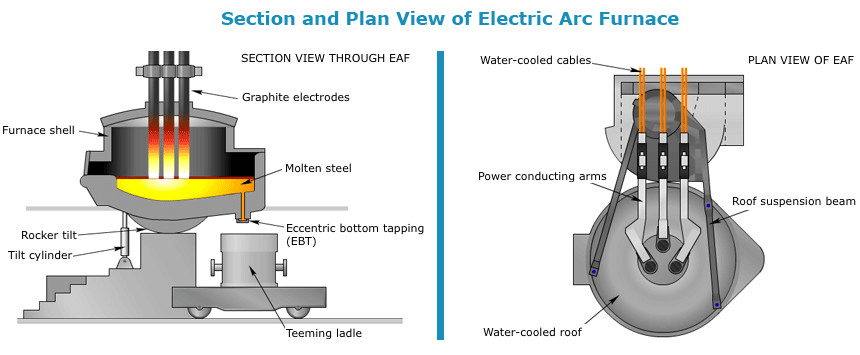

Application of RP Graphite Electrode

Electric furnace steelmaking mill is the largest user of graphite electrodes. Graphite electrodes used in steelmaking accounts for 70%-80% of the total graphite electrodes production. Graphite electrodes are used to conduct electric current into electric furnace, electric arcs generated between electrodes end and loaded materials can release large amount of heat for high temperature smelting.

(1) For Resistance Furnace

The graphitization furnace for producing graphite products, the furnace for glass melting, and the electric furnace for producing silicon carbide are all electric resistance furnaces. Materials loaded in these furnaces are not only heating resistances but also the objects to be heated. Usually, graphite electrodes for electric conduction are embedded in the wall of resistance furnace end part, so the graphite electrode used here is not continuously consumed.

(2) For the Production of Special Shaped Graphite Products

Graphite electrode workblank is also used to make a variety of special shaped graphite products such as crucible, mold, boat vessel and heating component. For example, in quartz glass industry, for every ton of electrofusion tube, 10t of graphite electrode blank is required, for every ton of quartz bricks, 100 kg of graphite electrode blank is consumed.