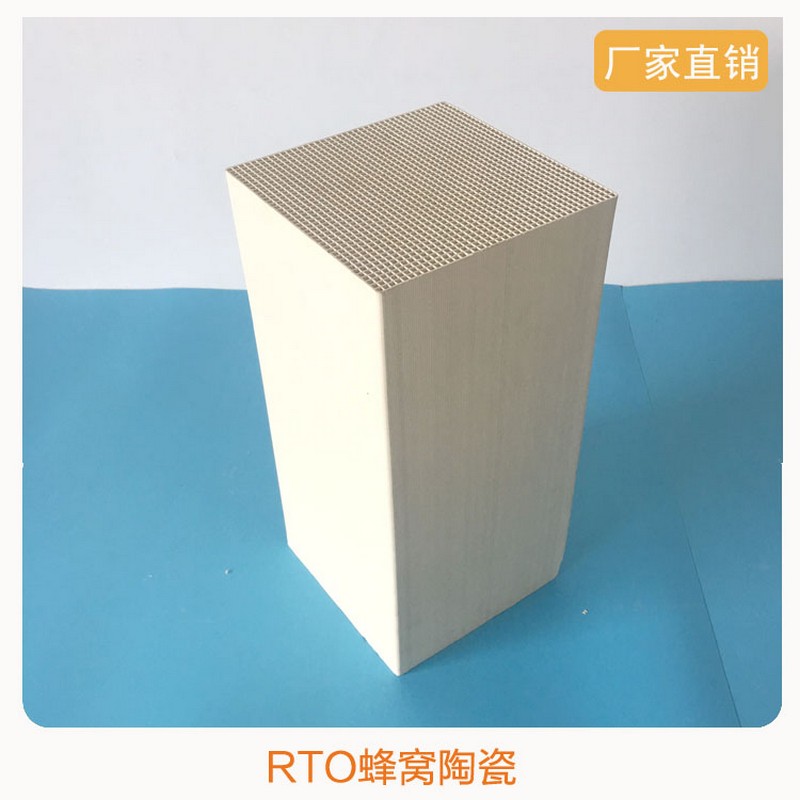

RTO refers to the regenerative thermal oxidation technology, and the English name is “Regenerative Thermal Oxidizer”. RTO regenerative thermal oxidation recovers heat by adopting a new unsteady heat transfer method. The principle is to heat the organic waste gas above 760℃to oxidize and decompose VOC in the exhaust gas into CO2 and H2O. The high-temperature gas generated by the oxidation flows through the special ceramic regenerator, and the ceramic body is heated and “heat-storing”, and the heat storage is used for preheating the organic exhaust gas that is subsequently introduced, thereby saving the fuel consumption of the exhaust gas heating. RTO technology is suitable for the treatment of low and medium concentration ( 100-3500mg/m2 ) waste gas with a decomposition efficiency of 95%-99%.

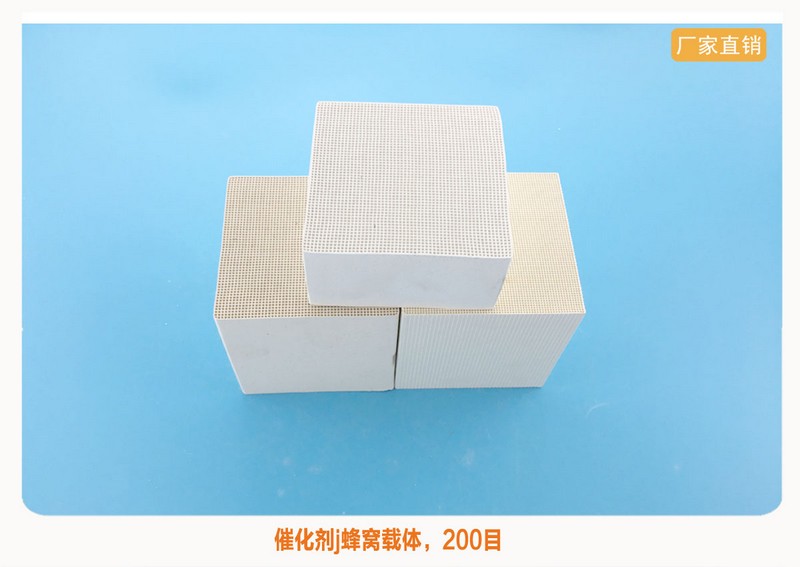

RCO refers to the regenerative catalytic combustion method, and the English is “Regenerative Catalytic Oxidation Oxidition”. The principle of RCO regenerative catalytic combustion is as follows: the first step is the adsorption of VOC molecules by the catalyst, and the concentration of the reactants is increased. The second step is to reduce the activation energy of the reaction and increase the reaction rate. By means of the catalyst, the organic waste gas can be anaerobicly burned at a lower light-off temperature, and decomposed into CO2 and H2O to release a large amount of heat. Compared with direct combustion, it has the characteristics of low light-off temperature and low energy consumption. In the case where the light-off temperature is reached, no external heating is required, and the reaction temperature is 250-400℃.

Main Size:

| L*W*G(mm) |

150x 150 x 300(150)

|

||||

| Number of Cell | 25×25=625 | 40×40= 1600 | 43×43=1849 | 50×50=2500 | 60×60=3600 |

| Width of Cell(mm) | 4.95 | 3.02 | 2.81 | 2.38 | 1.98 |

| Thickness of inner wall(mm) | 1.0 | 0.7 | 0.65 | 0.6 | 0.5 |

| Surface Area(m2/m3) | 577 | 886 | 950 | 1084 | 1294 |

| Opening Ratio(%) | 68 | 65 | 65 | 63 | 63 |

Physical Properties:

| Item | Aluminum Porceian-cordierite | Dense aluminum porcelain | Cordierite | Mullite-Cordierite | Mullite | Enamel |

| Density(g/cm3) | 2.0~2.3 | 2.4~2.6 | 1.6~1.9 | 1.7~2.0 | 2.0~2.4 | 1.7~2.0 |

| Bulk density (g/cm3) | 0.65~0.8 | 0.65~0.8 | 0.6~0.7 | 0.65~0.75 | 0.65~0.8 | 0.65~0.75 |

| Thermal Expansion Coefficient

(X10-6°C-1) (RT-800°C) |

≤6 | ≤6 | ≤3 | ≤3.5 | ≤5.5 | ≤6.5 |

| Specific heat capacity

(J/Kg.k) |

950~1150 | 1000~1200 | 900~1100 | 900~1100 | 1000~1150 | 900~1100 |

| Thermal Conductivity (w/m.k)(20-1000°C) | 1.5~2.0 | 1.5~2.0 | 1.2~1.8 | 1.4~1.9 | 1.5~2.0 | 1.4~1.9 |

| Thermal shock resistance Max Temperature(℃) | ≥400 | ≥300 | ≥450 | ≥350 | ≥350 | ≥300 |

| Advised Max Temperature(℃) | 1250 | 1350 | 1150 | 1250 | 1450 | 1200 |

| Water Absorption Rate(%) | ≤20 | ≤5 | ≤22 | ≤20 | ≤20 | ≤10 |

Chemical composition:

| Item | Aluminum Porceian-cordierite | Dense aluminum porcelain | Cordierite | Mullite-Cordierite | Mullite | Enamel |

| SiO2 | 25~35 | 25~35 | 45~55 | 40~50 | 25~35 | 68~72 |

| Al2O3 | 55~65 | 55~65 | 28~38 | 55~65 | 55~65 | 22~26 |

| MgO | 2~4 | 2~4 | 11~14 | 5~9 | ≤2 | ≤0.5 |

| Fe203+TiO2 | 1~4 | 1~4 | 1~3 | 1~3 | 1~4 | 1~3 |

| Others | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L*W*G(mm) | 150x 150 x 300(150) | ||||

| Number of Cell | 25×25=625 | 40×40= 1600 | 43×43=1849 | 50×50=2500 | 60×60=3600 |

| Width of Cell(mm) | 4.95 | 3.02 | 2.81 | 2.38 | 1.98 |

| Thickness of inner wall(mm) | 1 | 0.7 | 0.65 | 0.6 | 0.5 |

| Surface Area(m2/m3) | 577 | 886 | 950 | 1084 | 1294 |

| Opening Ratio(%) | 68 | 65 | 65 | 63 | 63 |