Magnesia Refractory Ramming Mass Features

Magnesia refractory ramming mass have high temperature volume stability.

Magnesia ramming refractory mass have resistant to erosion and wear.

Magnesia ramming refractory mass have good thermal shock resistance.

Magnesia refractory ramming mass have high load softening temperature.

Magnesia Refractory Ramming Mass Specification

| Item |

M-95 |

DM-90 |

| Al2o3(%) |

95 |

90 |

| Cr2o3(%) |

2.0 |

2.0 |

| Bulk Density(g/cm3) |

220℃*3h |

2.50 |

2.40 |

| Compressive Strength(Mpa) |

220℃*3h |

10 |

8 |

| 1500℃*3h |

20 |

20 |

Magnesia Refractory Ramming Mass Application

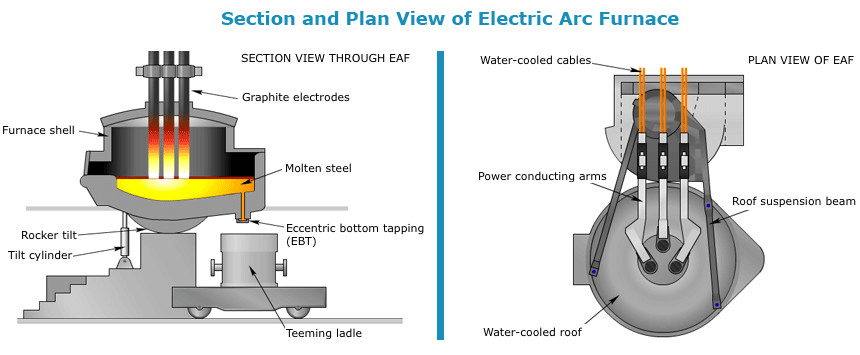

1. Magnesia ramming mass refractory can be used as a new furnace lining or as a lining repairing material, such as flat furnace bottom repair, converter lining repair, or steel mouth filling material.

2. Refractory magnesia ramming mass product is mainly used for electric furnace bottom filling, converter repairing material, refractory ramming mass can be used as filler around the tapping port.

3. Magnesium refractory ramming mass tundish is made of magnesium ramming material, refractory ramming mass is used for the working layer of the tundish. The service life after the whole pouring can be about 35 hours, magnesium refractory ramming mass is generally suitable for large tundish.

Magnesia Refractory Ramming Mass Manufacturing Process

Firstly, the high-purity magnesia and magnesium powder are calcined three times, so that the magnesia and magnesium powder are fully expanded and shrunk, and then the proportion of the magnesia particles is proportioned according to the formula, and then the binder, anti-cracking agent, stabilizer, stirring are added. Made into a dry magnesia ramming mass refractory.

Magnesia Refractory Ramming Mass Contruction Method

1.Magnesium refractory ramming mass add about 5% of the brine solution with a concentration of 35% before use, stir into a semi-dry mud, and dry or beat it manually or mechanically.

2.Magnesium ramming refractory mass are widely used as fillers for special parts such as electric furnaces, open hearth furnaces, converters, iron alloy refining furnaces, and steel taps. Magnesia ramming refractory mass is required to have good overall stability under the action of frequently changing temperature. Magnesium ramming material made of magnesia and hexahydrate solution has good normal temperature and high temperature performance.

Magnesia Refractory Ramming Mass Characteristics for Tundish

1.Refractory magnesia ramming mass have anti-steel water wash, anti-erosion.

2.Refractory magnesia ramming mass refractory have thermal shock performance is good.

3.Refractory magnesia ramming mass refractory have high temperature volume stability.

4.Magnesia ramming mass refractory have high temperature resistance, high load softening temperature.

Magnesia Refractory Ramming Mass Construction Process

1. First, ensure that the surface of the permanent lining is clean. Then install the impact board and the seat brick. The surrounding area is beaten with magnesium refractory ramming mass. Then the magnesium ramming material is poured into the bottom of the package and make the bottom thickness.

2. the tire mold is installed, the distance between the tire mold and the permanent lining is consistent, so that it reaches the thickness required for the working lining.

3.Pour the magnesium ramming refractory mass into the upper edge of the tire mold, and beat it with a rubber hammer, which is subject to the tamping.

4. Clean the scene, ignite the baking burner on the tire mold for small fire baking, baking temperature 180-270 ° C, time 2h or so, so that the magnesium ramming material hardens to obtain a certain strength, such as the temperature drop of the tire mold release to below 100 ° C

5. Check the lining of the working layer of the tundish and repair the furnace, if it is defective.

Magnesia Refractory Ramming Mass Using Precautions

1. Due to the special nature of magnesium refractory ramming mass, magnesia ramming refractory mass is forbidden to contact with water to prevent hydration.

2. Magnesia ramming mass refractory is forbidden to use magnesium ramming material ,which is agglomerated and of unqualified quality.

3. Determine the thickness of the lining of the working layer of the tundish according to the refractory ramming rass construction requirements.

Magnesia Refractory Ramming Mass Manufacturing Process

Firstly, the high-purity electrolytic magnesia and magnesium powder calcined three times. The purpose is to fully expand and shrink the electrolytic magnesia and magnesium powder. In expansion, contraction. The expansion and contraction rate is almost zero. Then the ratio of the particle size ratio is used. Add binders, anti-cracking agents, stabilizers, and other refractory materials. Stir into a dry mix.

Magnesia Refractory Ramming Mass Supplier in RS Refractory Bricks Factory

Rongsheng refractory castable factory has been engaged in refractory material industry for more than 20 years. Rongsheng refractory castable factory have a big technological team, there are more than 15 senior designers for the furnace & kiln. Refractory castable factory are good at different technological field, such as refractory bricks , refractory castable, lightweight insulation firebricks and prefabricated bricks according to client requirement.

Rongsheng refractory castable have rich refractory raw materials and 20 years experienced in the refractory bricks manufacturing. Rongsheng refractory ramming mass can provide specification and category as well as competitive price & high-grade quality refractory castable products.